Get Complete Project Material File(s) Now! »

Site layout planning

Site layout planning techniques perform to all projects where numerous physical means have to be located in a certain space. In general, the layout means an arrangement of everything required to complete production of any product. Really, the main purpose of site layout planning involves organizing work areas in the most efficient manners to be safe for personnel carrying out the work. Site layout planning can be defined as accommodation, in advance, of supporting temporary facilities, such as an electric generator, fuel storage, office trailers, fabrication areas, construction equipment, and warehouses and so on, at the proper location within the available site space. Even though all of these facilities are temporary, but they are great crucial to conduct and complete construction and production activities. In addition, any accidental event occurs in at least one of these facilities may be sufficient to endanger the workers’ life, escalate the occurrence of domino effect phenomenon, hinder and suspend work in the project for a period of time and even failure of the whole project. The purposes of conducting site layout planning allow a more active workflow at the site and make workers and equipment being more productive. Andayesh and Sadeghpour (2014) indicated that site layout models can be categorized into two classes. One is the static model, i.e. changes over time are not considered. The other is the dynamic model, i.e. changes over time are considered. The dynamic models focus on assigning an appropriate location of each temporary facility taking into account the dynamic changes in the requirements and site space availability. Huang and Wong (2015) stated that the site layout planning should be optimized taking into account multiple construction stages to avoid the excessive cost associated with the relocation of facilities and enhance efficiency.

The available construction site space should be exploited efficiently in order to minimize threats’ impacts, provide the safe working environment, and enhance workers’ productivity. There are many shortcomings associated with ineffective site layout plans:

1. Bad use of the available space.

2. Move long distances to carry out any operations on a construction site.

3. Skilled and qualified labors perform a lot of simple works.

4. The occurrence of various accidents on the site.

5. Suspension of work for a period of times.

6. The discomfort of labor when executing construction activities.

7. The complexity of monitoring and controlling the construction process

However, there is a consensus among most researchers that site layout planning is still a complex and challenging task (Zolfagharian and Irizarry 2014; Sanad et al. 2008; Zouein and Tommelein 1999). Sanad et al. (2008) indicated that site layout planning is a complex problem, due to the existence of several large tasks that need to be performed. Zouein and Tommelein (1999) demonstrated that utilizing site space efficiently to locate resources and facilities over the duration of a project is a complicated dilemma. In general, to develop and attain an efficient site layout plans, the construction managers and site planners must recognize the followings:

1. The facilities needed to be located on a construction site.

2. The available space and the size of the space required for each facility.

3. The best position that each facility should be located at within a construction site.

4. The reduction of failure risk due to natural or technological hazards.

5. The increase in workers’ satisfaction and safety.

6. The reduction of material handling.

7. The reduction of travel distance and unnecessary movements to minimize total transportation cost.

Unfortunately, all of these realizations cannot be achieved simultaneously, so the final site layout should take into account a balance among all factors affecting on it in order to acquire optimal site layout plan. Up until now, there is no regulation adopted to organize and manage site layout planning for avoiding or at least minimizing the risk of natural and/or technological hazards. Furthermore, the current site layout planning models consider a travel distance as a sole criterion in generating site layout plans (El-Rayes and Khalafallah 2005). Therefore, it is significant to develop a new model aims to minimize the risk of natural and/or technological hazard.

Criteria consideration for site layout planning

Site layout planning can be categorized according to the criteria that have been utilized for conducting optimization into:

Optimization models based on travel cost distance

In general, there are a lot of efforts have been exerted by the researchers to enhance construction site layout planning. Most of these efforts consider the travel cost distance as the most significant utility function and they aim to minimize it (Andayesh and Sadeghpour 2013, 2014; Astour and Franz 2014; Cheng and O’Connor 1994, 1996; Hegazy and Elbeltagi 1999; Zouein et al. 2002; Said and El-Rayes 2013; Zouein and Tommelein 1999; Huang and Wong 2015). They also applied several optimization algorithms to accommodate construction facilities at suitable positions within a construction site.

Hegazy and Elbeltagi (1999) developed an evolution-based site layout planning model called EvoSite. It is based on the implementation of a genetic algorithm (GA) to search for the optimum layout. El-Rayes and Said (2009) presented a model based on approximate dynamic programming (ADP) aiming to minimize the overall site layout costs in order to get optimal dynamic site layout of construction projects. Zouein and Tommelein (1999) developed a linear programming model to generate dynamic site layout, endeavoring to minimize the travel distance and relocation costs among all facilities. Andayesh and Sadeghpour (2013) developed an innovative dynamic model that is capable of producing optimized layouts over the project’s duration. The model is derived from the principles of an energy dominating physical system. The model is effectual due to its ability to assign space to facilities when they are required on the site and allows for the reuse of the space over time. Huang and Wong (2015) used the branch and bound algorithm to develop optimal site layout aims to minimize total cost. They indicated that the total cost consist of material transportation cost between facilities, set up cost of facilities and relocation cost for all facilities in each construction stage.

Furthermore, several researchers have used advanced technologies for site management. Cheng and O’Connor (1994, 1996) developed an automated site layout system called ArcSite. The proposed model uses the search by elimination principle available in the geographic information system (GIS) to identify the best position for each supporting temporary facility and generate the optimal layout. Andoh et al. (2012) presented a framework for the continuous tracking of the 4D status of a dynamic construction site, utilizing radio frequency identification (RFID), the global positioning system (GPS) and the GIS, in order to achieve project objectives. Astour and Franz (2014) described the problems associated with site layout planning and developed a model utilizing building information modeling (BIM) to generate a 3D site layout plan. Kang and Seo (2012) utilized GIS for determining the optimal layout of a haul route for large earthmoving projects.

Optimization models for consideration of safety issues

Other researchers concerned with maximizing safety conditions by considering the safety operation of some supporting facilities, crane, and facilities containing hazardous material for instance. They asked construction managers to give them higher priority of controlling over construction phase (Elbeltagi and Hegazy 2003; El-Rayes and Khalafallah 2005; Sanad et al. 2008; Dagan and Isac 2015).

Elbeltagi and Hegazy (2003) proposed site layout planning optimization model that considers other relevant criteria, in addition to the travel distance, such as site safety and productivity. They presented the construction site and facilities as a multi-unit. The GA was used to achieve an optimal site layout. Sanad et al. (2008) developed an optimization site layout model by utilizing a GA and considering safety aspects and the actual route between facilities as the main criteria in generating optimal site layout. El-Rayes and Khalafallah (2005) presented a model capable of maximizing construction site safety and minimizing travel cost distance within a construction site. They suggested providing an adequate distance between hazardous facilities and any other potential targets. The safety criteria that were considered in this model are (1) crane safety operation and (2) control of hazardous materials. Although the model did not take into account hazards from all other construction facilities, but it is still vital because it illustrated the trade-off between safety and travel costs. Dagan and Isaac (2015) proposed a planning method in order to protect workers from injuries and keep them at a safe distance from each other. The proposed method depends on the assumption that the hazardous situation is a result of the interaction between the reinforcing and counteracting characteristics of the workers. Moreover, they embedded the definition of a minimum safe distance between workers. In addition, 3D time-space diagram is embraced in the methodology to analyze the dynamic movement of workers on the construction site.

Determining the optimal path

Finding the safest routes for movement within a construction site is also still a scientific challenge. Soltani and Fernando (2004) developed a framework for construction site path planning analysis, considering travel cost, visibility, and safety as multi-criteria for path evaluation. Choi et al. (2009) developed software called (dump traveler) to determine the optimal haulage routes from mines for dump trucks. The software is based on a combination of multi-criteria evaluation and least-cost path analysis. Choi and Nieto (2011) created a software application called the Google Earth Based Optimal Haulage Routing System (GEOHARTS) to find the optimal route for dump trucks in construction and mining sites. It is based on the capability of Google Earth and the least-cost path algorithm. Moreover, the software has the ability to generate the optimal haulage routes that ensure the shortest travel time and lowest fuel cost between loading and dumping areas.

There is a frequent trend among most researchers to use GA to find the optimal path. las Mercedes Gómez-Albarrán et al. (1997) created an algorithm called GALO, which integrated GA and Lee’s algorithm in order to find the shortest path between nodes in circuit routing. Gen et al. (2001) utilized GA for solving problems associated with network analysis, especially those related to finding the shortest path. Soltani et al. (2002) conducted a comparison among three optimization techniques to evaluate their efficiency in finding the optimal paths on construction sites. These algorithms are GA, Dijkstra’s algorithm, and the A* algorithm. Saha et al. (2005) utilized Dijkstra’s algorithm and least-cost path analysis in route planning of areas susceptible to landslide. Xu and Lathrop (1994) improved the cost simulation model. They enhanced the cost-path tracking by recording path information using two layers. Feldman et al. (1995) used remotely sensed data, GIS, and least-cost analysis to carry out pipeline routing.

Collischonn and Pilar (2000) developed a least-cost path algorithm to determine the best path for linear features such as roads and canals. The algorithm is highly dependent on the raster structure, which is usually utilized in GIS. Yu et al. (2003) upgraded traditional algorithms for practical roadway planning. They took into consideration the spatial distances and the existence of tunnels and bridges, in finding the least-cost paths for roadway planning. Rees (2004) utilized Dijkstra’s algorithm to calculate the least-cost paths on a Digital Elevation Model (DEM) to find footpaths in a mountainous area in Wales. The results showed that the existing footpaths did not coincide with the calculated least-cost paths and did not follow the route that took the least time. Akkanen and Nurminen (2001) conducted a review study to demonstrate the evolution of routing algorithms. They concluded that algorithms have improved over time. They also indicated that the engineering attitude should be considered when utilizing any of these algorithms. Kang and Seo (2012) elaborated a GIS-based method for determining the optimal haul route for earthmoving. They implemented a least-cost path analysis to calculate the route with the shortest weighted distance between cut and fill areas. Mahdjoubi and Yang (2001) created Virtual Construction Material Router (VCMR) software. It is composed of GIS, computer-aided design, and fuzzy logic. It enables the simulation of several potential scenarios, where site managers can select the best routes for transferring materials within a construction site. Modesti and Sciomachen (1998) performed a study to find the shortest path in urban transportation networks considering travel time, travel cost, and user preferences as main criteria to identify the optimal path. Sung et al. (2000) identified the shortest path for time-dependent networks based on Dijkstra’s algorithm. In these networks, the time interval is the basic unit to determine the flow speed for each link. Gao et al. (2007) indicated that evacuation is very crucial in emergency management. They developed a model to minimize the evacuation time through performing a simulation of a route/time swapping process utilizing a heuristic algorithm to get the optimal routes.

Risk management studies

Several studies have tackled the subject of construction risks and injuries occurring during the construction process, proposed methods to facilitate evacuation and reduce losses and casualties in cases of emergency, and the economic cost of implementing risk management while ignoring the impact of site layout on minimizing these losses.

Raz and Michael (2001) developed a questionnaire to identify the tools that are most frequently utilized and contributed by enhancing project risk management. Akintoye and MacLeod (1997) found that risk management during construction is very significant in reducing losses and increasing profitability, and also conclude that the risk analysis and management depend entirely on experience, judgment, and intuition. They found that risk management techniques are rarely utilized due to a lack of knowledge and suspicion about the appropriateness of these techniques in giving the best results. Kim et al. (2013) stated that the repetitive occurrence of similar accidents in the construction industry is a prevalent feature. They proposed an accident automated information retrieval system that composes a query set that combines building information modeling (BIM) objects with a project management information system. Users can noticeably reduce query generation and can easily avoid risks by receiving similar past accident cases that may happen while they work. Carr and Tah (2001) proposed a model for qualitative risk assessment based on a hierarchical risk breakdown structure. In this model, the relationship between project sources and consequences on project performance can be quantified utilizing a fuzzy approach.

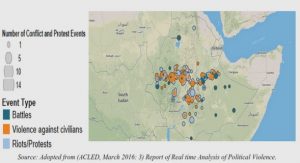

Charrière et al. (2012) talked about the importance of risk communication as one of the procedures that should be conducted to enhance the preparedness of inhabitants in order to minimize risk disaster. They proposed a visualization utilizing GIS as one of the best ways of propagating information about spatial phenomena. Belinfante et al. (2012) conducted a study to propose a way of determining the economic value of geospatial information in risk management. They claimed that the probable value of geo-information in risk management is high due to its ability to enhance the speed and quality of decision-making in disaster and risk management. This, in turn, enhances the possibility to minimize losses and damage. Kang et al. (2013) developed a risk management visualization model that has the capability to analyze the degree of risk in construction projects by collecting risk information utilizing quantifying methodologies like the Analytical Hierarchy Process (AHP) and fuzzy techniques.

Table of contents :

CHAPTER 1 General Introduction

1.1 Background

1.2 Statement of the problem

1.3 Research justifications

1.4 Research objectives

1.5 Significance of study

1.6 Thesis organization and contribution

1.7 Résumé du chapitre 1

CHAPTER 2 Related Work

2.1 Project life cycle

2.1.1 Feasibility study

2.1.2 Design phase

2.1.3 Procurement phase

2.1.4 Construction phase

2.1.5 Operation and maintenance phase

2.2 Site layout planning

2.3 Temporary facilities

2.4 Optimal path

2.5 Previous studies

2.5.1 Criteria consideration for site layout planning

2.5.1.1 Optimization models based on travel cost distance

2.5.1.2 Optimization models for consideration of safety issues

2.5.2 Determining the optimal path

2.5.3 Risk management studies

2.6 Hazard

2.7 Vulnerability

2.7.1 Physical vulnerability

2.8 Risk

2.9 Interaction matrix

2.9.1 Generating the interaction matrix

2.9.2 Mathematical operations on interaction matrix

2.10 Space syntax

2.11 Optimization algorithm

2.11.1 Evolutionary algorithm

2.11.2 Evolutionary approach technique

2.12 Dijkstra’s algorithm and least cost path analysis

2.13 Geographic information system (GIS)

2.14 Simulation technique and uncertainty analysis

2.15 Résumé du chapitre 2

CHAPTER 3 Research Methodology and Model Development

3.1 Methodology

3.1.1 Meticulous literature review

3.1.2 Risk analysis

3.1.3 Utility function and optimization

3.1.4 Numerical results

3.2 Developing deterministic model

3.2.1 Generating optimal layout of construction site (phase 1)

3.2.1.1 Site and facility representation

3.2.1.2 Hazard and vulnerability interaction matrix

3.2.1.2.1 Modeling hazard interaction matrix

3.2.1.2.2 Modeling vulnerability interaction matrix

3.2.1.3 Optimization technique (evolutionary algorithm)

3.2.1.3.1 Utility function

3.2.1.3.2 Model layout constraints

3.2.1.4 Effect of space configuration (mean depth parameter)

3.2.1.5 Developing spatial risk map utilizing GIS

3.2.2 Finding optimal paths (phase 2)

3.3 Developing a probabilistic model

3.3.1 Hazard modeling

3.3.2 Physical vulnerability modeling

3.3.3 Risk modeling

3.3.4 Probabilistic model utility function

3.4 Spatial methods for model validation

3.5 Résumé du chapitre 3

CHAPTER 4 Model Implementation and Results Discussion

4.1 Implementation of deterministic model

4.1.1 Case study description

4.1.2 Optimization process and discussion of results

4.1.2.1 Optimal layout result

4.1.2.2 Optimal path result

4.2 Implementation of a probabilistic model

4.3 Résumé du chapitre 4

CHAPTER 5 Conclusion and Perspectives

5.1 Summary of the research and findings

5.2 Conclusion

5.3 Directions of future research

5.4 Résumé du chapitre 5

Author’s publication and contribution list

Bibliography