Get Complete Project Material File(s) Now! »

Chapter 4. Characterisation and Drainage Mechanism of Microbubble Dispersion

Introduction

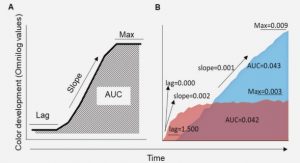

Literature review in Section 2.3 has identified that the characterisation study on microbubble dispersion has been limited on synthetic surfactants, although natural surfactants have demonstrated promising potential for bioremediation applications. In this chapter, characterisation studies of microbubble dispersion made from rhamnolipid are performed. Preliminary tests are carried out to establish desirable apparatus set-up and mixing conditions to generate microbubble dispersions. Properties of the dispersion – stability, size distribution and gas hold-up are investigated under various environmental conditions. In particular, stability is the focus of the characterisation study because it is a critical property with implications for bioremediation applications. Stable microbubbles will travel further in subsurface and reach deeper into contaminated zones (Wan et al., 2001).

To help understand whether rhamnolipid biosurfactant delivers properties comparable to chemical surfactants, two chemical surfactants (tergitol and SDS) are used in some tests for comparison with rhamnolipid, and the results are also compared with findings in the literature. Tergitol surfactant is chosen because it has been used in a number of studies to make microbubble dispersion and tested to be biodegradable and biocompatible with a variety of contaminant-degrading bacteria (Matsushita et al., 1992; Rothmel et al., 1998; Wang & Mulligan, 2004a). SDS is chosen because it has been commonly used for making microbubble dispersion and was anioic in nature like rhamnolipid (Wan et al., 2001; Yan et al., 2005). However, SDS is not biocompatible with bacteria (Rothmel et al., 1998), and is a common reagent used to disrupt or lyse bacterial cell membrane.

As discussed in Section 2.3, the drainage models for microbubble dispersion in the literature appear to be incomplete. An improved drainage mechanism and model are proposed using the drainage data obtained from the characterisation study of the rhamnolipid microbubble dispersion in this study to fill the gap in current understanding.

The following objectives are achieved in this chapter.

- To develop the best possible generator configuration in order to provide improved dispersion stability;

- To investigate microbubble dispersion properties including drainage/stability, gas hold-up and size distribution under various environmental conditions, such as pH, ionic strength and surfactant concentration;

- To develop and improve drainage model specific to microbubble dispersion because drainage models in the literature have yet to provide a satisfactory explanation to the drainage behaviour observed in microbubble dispersion.

Preliminary Testing

Mixing Speed and Duration

Studies have shown that mixing speed and duration can affect the properties of microbubble dispersion. Sebba (1987) found that microbubble dispersion was formed at mixing speed greater than 4,000 rpm. The commonly used mixing speeds quoted in the literature range from 6,000 rpm to 13,000 rpm, with 8,000 rpm being the most popular choice (see Section 2.3.2). Studies of the contribution of mixing duration have not yielded consistent conclusions. While some report that mixing duration does not have significant influence on increasing dispersion properties (Jauregi et al., 1997), others have shown that dispersion stability fluctuates for stirring times of 1 to 5 minutes (Save & Pangarkar, 1994). Preliminary tests were therefore performed to identify the suitable mixing speed and duration for this study (see Appendix III for experimental data). Microbubble dispersion was made using setup 1 with a flat disk and two baffles (see Section 3.2 or 4.2.3).

The tests were first performed with a high surfactant concentration at 20,000 mg/L rhamnolipid to eliminate any effects resulting from lack of surfactant molecules. The liquid drainage curves were shown in Figure 4-1 and the stability and gas hold-up values derived from Figure 4-1 were summarised in Table 4-1.

The sh ape of the drainage s hown in Figure 4-1 does not vary much with varying mixing speed a nd duratio n. The results in Table 4-1 indica te that increasing the mixing speed from 8,000 rpm to 10,0 00 rpm sign ificantly d ecreased st ability (P<0.05). Henc e, the mixi g speed of 8,000 rpm is preferred ov r 10,000 r pm. Increasing mixing duration f rom 3 min tes to 6 minute results in a significant reduction in stability (P<0.05). Therefore m ixing duration of 3 minute is preferre d. It was also observed that at mixing speed of 10,000 rpm the vo lume of microb ubble dispersion beca e stabilized after abo ut 1.5 minutes and further mixing resulted in heating up the dispersion . The exc essive heat may have a detrimental effect on the dispers ion stability .

Neither the mixing speed nor duration has significant influence on gas hold-up values (P>0.05).

Overall, a mixing speed of 8,000 rpm for a duration of 3 minutes is a suitable combination for making microbubble dispersion and is used for subsequent experiments.

Rhamnolipid Concentration

A wide range of rhamnolipid concentrations, varying from 300 mg/L to 20,000 mg/L, were tested to identify a suitable range for further testing. The tests were performed using setup 1 at mixing speed of 8,000 rpm for 3 minutes. Rhamnolipid solutions at higher concentrations would be less economical in field-scale remediation, and so it is desirable to produce microbubble dispersions with relatively low rhamnolipid concentrations that do not compromise the dispersion’s properties. The liquid drainage curves were shown in Figure 4-2 and the stability and gas hold-up values derived from the drainage curves were summarized in Table 4-2.

Under equal mixing conditions, the microbubble dispersion created at a rhamnolipid concentration of 300 mg/L demonstrated a stability that is significantly lower than those at higher rhamnolipid concentrations (P<0.05), and the dispersion did not display the characteristic thickness as produced with rhamnolipid concentrations 500 mg/L or greater. Furthermore, it was observed that at 300 mg/L the microbubbles rose to the dispersion surface at a much faster rate than those from higher rhamnolipid concentrations, leaving a large volume of liquid phase at the bottom. The rapid ascent of the microbubbles indicated that the dispersion was very unstable.

Increasing rhamno lipid conc ntration fr om 300 m g/L to 500 mg/L and above significantly increas ed the dispersion stability (P<0.0 5), but the increasing the concentration from 1,000 mg/L t 10,000 m g/L did not have a significant effect on the st bility (P>0.05).

The ga hold-up values incre sed signifi cantly whe n the rhamnolipid conc entration i ncreased from 3 00 mg/L to 500 mg/L and above (P<0.05), but for con centrations between 5 00 mg/L and 20,000 mg/L, the gas hol -up values stayed constant (P>0. 05).

Based on the preliminary characteris tion resul ts of the microbubbl e dispersi ons, the rhamnolipid conc ntrations selected for further te ting were 500 mg/L (low), 1,00 0 mg/L (mediu m) and 4,00 0 mg/L (high).

The Appar atus

Setup 1 was the original mixer configur ation used to generat microbub ble dispers on. The setup w as based o n the original apparat us describ d in the e rly literatu re (Rothm el et al., 1998; S ebba, 1987 ). Other researchers m odified th original s etup to 1) replace the flat disk with a propeller and 2) use baffles instead of 2 (Jauregi et al., 1997). Schematic s of the setups were show n in Figure 4-3. Both setups were tested to determine the one tha t would produc e more stable microb ubble dispersion. The test was carried o ut for 1,000 mg/L rhamnolipid concentration at a mixing speed of 8,000 rpm for 3 minutes.

Summary

As a r esult of th e prelimina ry testing, the follow ing mixin g condition s and rha mnolipid concen trations are selected for further stu dy:

-

-

- Set up 1 with a flat disk and two baffl es;

- Mix ing at 8,000 rpm for 3 minutes; and

- Rha mnolipid concentrations of 500 m g/L, 1,000 mg/L and ,000 mg/L.

-

-

Abstract

Acknowledgements

List of Figures

List of Tables

List of Acronyms

Chapter 1. General Introduction

1.1. Research Objectives

1.2. Thesis Hypotheses

1.3. Thesis Outline

Chapter 2. Literature Review

2.1. Introduction

2.2. Surfactant and Biosurfactant

2.3. Characterisation of Microbubble Dispersion

2.4. Environmental Applications

2.5. Bacterial Adhesion to Surfaces/Interfaces

2.6. Theoretical Models for Bacterial Adhesion

2.7. Surface Thermodynamic Approach to Bacterial Adhesion

Chapter 3. Materials and Experimental Methods

3.1. Materials

3.2. Generation of Microbubble Dispersion

3.3. Characterisation Studies for Microbubble Dispersion

3.4. Bacteria Culture and Preparation

3.5. Adsorption of Surfactant on Bacteria

3.6. Bacterial Survival Test

3.7. Bacterial Cell Surface Hydrophobicity

3.8. Bacterial Cell Drainage from Microbubble Dispersion

3.9. Surfactant Analysis Procedure

3.10. Magnesium Analytical Procedure

3.11. Polyacrylamide Gel Electrophoresis (PAGE) Analysis of Lipopolysaccharide

3.12. Microscopy Examination

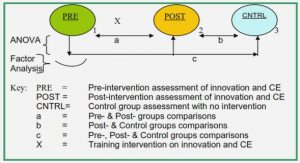

3.13. Treatment of Data and Statistical Analysis Procedure

Chapter 4. Characterisation and Drainage Mechanism of Microbubble Dispersion

4.1. Introduction

4.2. Preliminary Testing

4.3. Microbubble Dispersion Stability

4.4. Liquid Drainage Model

4.5. Gas Hold‐Up Measurement

4.6. Size Distribution

4.7. Comparison with Synthetic Surfactants

4.8. Effect of Bacteria Addition

4.9. Drainage Mechanism

4.10. Chapter Summary

Chapter 5. Bacteria/Microbubble Interaction and Surface Thermodynamic Modelling of the Interaction

5.1. Introduction

5.2. Bacterial Adhesion to Microbubble Dispersion

5.3. Bacteria/Surfactant Interaction

5.4. Microbial Adhesion to Hydrocarbon Assay for Cell Surface Hydrophobicity Measurement

5.5. Contact Angle Measurement

5.6. Bacterial Cell Surface Thermodynamics and Hydrophobicity with Surfactant Present

5.7. Surface Thermodynamic Modelling of Bacteria/Microbubble Interaction

5.8. Chapter Summary

Chapter 6. Visualisation of Bacteria/Contaminant/Microbubble Interaction and Surface Thermodynamic Modelling of the Interaction

6.1. Introduction

6.2. Visualisation of Microbubble/Contaminant Interaction

6.3. Visualisation of Microbubble/Contaminant/Bacteria Interaction

6.4. Surface Thermodynamic Modelling of Microbubble – Contaminant – Bacteria Interaction

6.5. Implication for Bioremediation

6.6. Chapter Summary

Chapter 7. Conclusions and Recommendation for Future Research

7.1. General Summary

7.2. Conclusions and Implications for Bioremediation

7.3. Significant Contributions

7.4. Recommendations for Future Research

References

GET THE COMPLETE PROJECT

A Study of Rhamnolipid Microbubble Dispersion for Bioremediation Applications