Get Complete Project Material File(s) Now! »

COOLING WATER SYSTEMS IN POWER SUPPLY FACILITIES

This PhD manuscript focuses on the study of the corrosion of copper alloys used in the production of piping material for the electricity-generating plants, like fossil fuel, nuclear, hydroelectric, cogeneration and geothermal power plants.

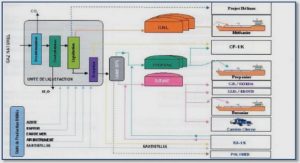

In thermal generating plants, the chemical energy in the fuel is converted into thermal energy to heat water, making steam. The steam turns an engine (turbine), creating mechanical energy to run a generator. Magnets turn inside the generator, producing electric energy (Figure 1-1). To make thermal electricity, nuclear fissile fuel, coal, oil, waste and gas are used.

A very important part of the process occurs in the condensers and cooling water system. The steam exits the turbines and passes over cool tubes in the condensers. The condensers capture the exhausted steam and transform it back to water, at very low pressure. The cooled water is then pumped back to the boiler to repeat the heating process. At the same time, water is piped from a reservoir or a river or sea to keep the condensers constantly cool. This cooling water, now warm from the heat exchange in the condensers, is released from the plant.

The condenser is a particular critical component in a power plant, because condenser tube leaks can affect many other components in the steam-water cycle and besides mechanical problems, the most frequent cause for tube leaks is corrosion [4].

TYPES OF CONDENSERS

Condensers are heat exchangers, i.e., the essential heat transferring elements in cooling systems. It is the device used for transfer heat between two or more fluids at different temperatures and in thermal contact [5]. The fluids can be either liquids or gases, and are ideally separated by a heat transfer surface [6].

Heat exchangers could be classified in many different ways such as according to transfer processes, number of fluids, surface compactness, flow arrangements, heat transfer mechanisms, type of fluids and industry.

Common flow arrangements of the fluids in a heat exchanger are classified in single or multiple pass (Fig. 1-2). When a heat exchanger’s fluids pass each other more than once, a heat exchanger is called a multi-pass heat exchanger. If the fluids pass each other only once, the heat exchanger is called a single-pass heat exchanger. The choice of a particular flow arrangement is dependent on the required exchanger effectiveness, available pressure drops, minimum and maximum velocities allowed, fluid flow paths, packaging envelope, allowable thermal stresses, temperature levels, piping and plumbing considerations, and other design criteria.

Considering the type of coolant, condensers may be cooled by water, air or water spray. A water-cooled condenser is a heat exchanger that removes heat from refrigerant steam and transfers it to the water flowing inside it. Thus, the refrigerant steam condenses on the outside surface of a tube and gives up heat to the water flowing inside the tube.

An air-cooled condenser is a direct dry cooling system where the steam is condensed inside finned tubes, and the cooling media (air) is blown outside the finned tubes. As there is no intermediate surface condenser like indirect dry cooling, the overall performances are better. Usually this type of condenser is used in small plants.

Figure 1-2: Classification of heat exchangers according to flow arrangements (a) and example of single and multiple pass heat exchangers (b) (adapted from John Willey [7]).

Like water-cooled condensers, evaporative-cooled condensers first transfer heat to the water and then from the water to the outdoor air. The evaporative condenser combines the functions of a cooling tower (transfer waste heat to the atmosphere through the cooling of a water stream to a lower temperature) and a condenser in one package. The condenser water evaporates directly off the tubes of the condenser.

TYPES OF COOLING WATERS

Different water resources are normally used in water-cooled condensers, depending of their availability: freshwater, seawater and brackish water1. Seawater-based cooling is mainly used in refineries and large power plants. Seawater is an excellent cooler: huge amounts are available and it is usually very clean. It presents high salinity (mainly due to sodium chloride) and electric conductivity, from 40.0 to 50.0 mS.cm-1 which is at least about 200 times higher than the conductivity of a river water.

1 Brackish water is water that has more salinity than freshwater, but not as much as seawater. It may be a mix of seawater and freshwater.

The pH of seawater is dependent on the predominance of aqueous CO2, bicarbonate (HCO3-) or carbonate (CO32-) ions. Usually, the pH of seawater is alkaline, between 7.9 and 9.0. For non polluted waters, it ranges from 8.0 to 8.4 and decreases with an increase of temperature [8]. At this pH, the HCO-3 ions predominate. Carbonate ions concentration increases with increasing pH, and when more CO2 dissolves in seawater, the pH becomes more acidic (Figure 1-3).

When CO2 from the atmosphere reacts with seawater, it immediately forms carbonic acid (H2CO3), which in itself is unstable. This further dissociates to form bicarbonate and carbonate ions. The bicarbonate and carbonate ions are responsible for the buffering capacity of seawater, i.e. seawater can resist drastic pH changes even after the addition of weak bases or acids. The carbonate ions can react with calcium ions (Ca2+), which are in excess in seawater, to form calcium carbonate (CaCO3), the material out of which the shells of mussels, the skeleton of corals and the exoskeleton of some microalgae is made of.

Figure 1-3: Distribution of CO2, HCO-3 and CO2-3 concentrations as a function of pH. Seawater has a pH value around 8.2.

CONSTITUENT MATERIALS OF COOLING WATER SYSTEMS

The selection of materials in cooling systems is a complex process. It must be a compromise between the requirements due to the chemistry of the water and the operational requirements of the system. A variety of materials have been used for feed-water heater and condenser tubes.

In seawater, the most common include coated carbon steel, titanium, copper alloys (aluminum brass, 90Cu-10Ni and 70Cu-30Ni copper-nickel alloys [9]), admiralty brass and Monel (70% nickel, 30% copper), sometimes also 304 stainless steel is used. Condenser tubes are often made of cuprous materials.

Titanium has been now largely used, in power plants surfaces condensers, desalination plants, chemical process and refinery heat exchangers. Titanium is known to offer an exceptional resistance to corrosion, attributed to its surface oxide film, 5-10 nm thickness, formed immediately on exposure to air. The natural titanium oxide film is dense and stable anatase (TiO2) and protects the inner metal from further oxidation [10-12]. There are no case histories that document microbial induced corrosion of titanium and its alloys [10, 13, 14].

Stainless steels consist of a group of iron-based alloys which contain a minimum of 10.5% and maximum 30% of chromium and are one of the most widely used materials and have many different applications; they are divided in four main groups based on their microstructure: ferritic, austenitic, martensitic and austenitic-ferritic (duplex). Other elements may be summed up to provide specific characteristics to the alloy, such as nickel, molybdenum, copper, titanium, aluminum, silicon, niobium and nitrogen; e.g. austenitic stainless steels that is usually alloyed with Ni, for example 18Cr-Ni (AISI 304) [15, 16]. The corrosion resistances of stainless steels are due to the formation of a thin passive film of chromium-rich oxide which works as a barrier against ion diffusion between the alloy and the ambient phase; this protective layer chromium-oxide develops during routine exposure to the oxygen content in the atmosphere. The passivity of stainless steel can break down under the following environments: a) dilute and concentrated HCl, HBr, and HF, and salts that hydrolyze these acids; b) oxidizing chlorides such as FeCl3, CuCl2, or NaOCl; c) seawater, except for brief exposures or when cathodically protected; and c) some organic acids including oxalic, lactic, and formic acids [14, 16, 17].

Copper and copper alloys are commonly used in condensers and heat exchangers due to their high thermal and electrical conductivity, mechanical workability and good resistance to corrosion and macrofouling. Those criteria have lead for a long time to the selection of copper alloys such aluminum brass, 70Cu-30Ni alloy or 90Cu-10Ni alloy, to be used in seawater [10, 14, 18, 19]. Alloying nickel and small amounts of iron into copper improves the corrosion resistance; therefore Cu-Ni alloys are preferred in marine environments due to the formation of a thin, adherent, protective surface film which forms naturally and quickly upon exposure to clean seawater. That surface film is complex and predominantly made up of cuprous oxide, often containing nickel and iron oxides, cuprous hydroxychloride and cupric oxide [18, 19]. Nickel provides passivity in acidic solutions while Cu is protective in more alkaline solutions [20]. Additionally, Cu-Ni alloys are also chosen in seawater because of its resistance to macrofouling; the reason for their antifouling behavior is still not fully understood, but it may be result from the action of a low level of steady discharge of cupric ions [21]. Despite copper’s reputation for toxicity, copper alloys are vulnerable to microbial induced corrosion, especially when long periods of stagnation are involved or flow is intermittent. Differential aeration, selective leaching, under-deposit corrosion, and cathodic depolarization have been reported as mechanisms for MIC of cooper alloys [14, 19, 20]. The application fields of copper and its alloys can be classified into five sections as shown in Table 1-1.

COOLING WATER SYSTEMS OPERATING PROBLEMS

The major problems associated with cooling systems are: scaling, fouling, biofouling and corrosion. If these problems are not properly controlled, they can have a direct, negative impact on the value of the entire process or operation [13].

• Scaling

Scale refers a dense coating of predominantly inorganic material formed on the surface of equipment in the presence of water; it takes place when dissolved ions in the water exceed the solubility of a given mineral. Such a process frequently occurs when surfaces are overheated. The common precipitates are calcium carbonates, sulfates or silicates. The principal factors determining whether scale is forming are temperature, pH, water quality, concentration of scale-forming material present, hydrodynamic conditions and influence of other dissolved materials, which may or may not be scale-forming. In cooling systems, the most frequent type of scale found is a deposit of calcium carbonate [23]. Scale formation damage the heat transfer and reduces flow velocities inside the condenser tubes, its solution, normally requires costly chemical softeners [24].

• Fouling and biofouling

The accumulation of solid material, other than scale, in a way that hampers the operation of plants equipment or contributes to its deterioration deposition of suspended material in heat exchange equipment is called fouling. Foulants can come from external sources such as dust around a cooling tower or internal sources such as by-products of corrosion. Examples are: dirt and silt, sand, corrosion products, natural organics, microbial masses, aluminum phosphates, iron phosphate. The factors that influence fouling in a cooling system are the water characteristics, temperature, flow velocity, microbial growth, corrosion and contamination [25].

Cooling circuits of power plants are ideal incubators for microorganisms because they offer plenty of water, are maintained at temperatures between 30°C to 60°, at pH of 6 to 9, have good aeration and provide a continuous source of nutrients, such as inorganic or organic compounds; microorganisms are those organisms that cannot be seen individually with the unaided human eye. The microorganisms present in cooling water circuits can be divided into planktonic or sessile cells. Sessile ones attach to surfaces and form what is known as biofilm.

The development of a biofilm is a multistage process involving the following major steps (Fig. 1-4): a) formation of an organic conditioned film on the solid surface by adsorption of biomolecules such as proteins, b) transport of microorganisms from the water to the surface, c) adhesion of microorganisms onto the surface, d) replication of the attached cells and production of exopolymers, e) detachment of parts of the biofilm that are swept along by the flowing water to repeat the process of biofilm formation elsewhere. Biofouling is a consequence of biofilm formation and is able to change the electrochemical properties of the metal-water interface, both in aerobic and anaerobic environments; the significant negative effects of biofouling are the blockage of water free flow in the cooling circuit and consequent mechanical damage to pumps, clogging of condenser tubes, reduction of the heat transfer efficiency (having a direct effect on the efficiency of the thermal cycle of power plants), and microbiologically influenced corrosion (MIC) also called biocorrosion.

Figure 1-4: Principal steps in the biofilm development: 1) Initial reversible attachment of free swimming micro-organisms to surface, 2) Permanent chemical attachment, single layer, bacteria begin making slime, 3) Early vertical development, 4) Multiple towers with channels between, maturing biofilm, 5) Mature biofilm with seeding/dispersal of more free swimming micro-organisms (Graphic by Peg Dirckx and David Davies, 2003 Center for Biofilm Engineering Montana State University).

• Corrosion

Several definitions of corrosion have been given. Despite different definitions, it can be observed that corrosion is basically the result of chemical or electrochemical interaction between a metal and environments; in cooling water circuits, this result in the gradual loss of metal thickness or even penetration of tube wall, which can cause leakage of process fluids into the cooling water or vice-versa. The main factors that affect corrosion are the oxygen and other dissolved gases, the dissolved and suspended solids, the pH, the velocity, the temperature and the microbial activity [21, 26]. Table 1-2 shows the corrosion mechanisms that are encountered in cooling water systems.

Table 1-2: Corrosion mechanisms that have caused problems in power plant cooling water systems under certain conditions (adapted from Syrett et al. [4]).

(a) W: water side problem; S: steam side problem; WS: both sides; N: not a problem; w: small sensibility on water side; s: small sensitivity on steam side; (b) Includes stress-corrosion cracking and hydrogen embrittlement; (c) Possible problem only if sulfides are present; (d) Problems have occurred for similar alloys; (e) Induced in adjacent copper alloys, iron, and carbon steels when used in seawater or other highly conductive waters; (f) Brittle titanium hydride may form and crack if excessively high cathodic protection currents are applied.

As the objective of this work is to study the corrosion behavior of copper alloys (70Cu-30Ni and Al brass) in seawater environments, only the corrosion mechanism associated with these two materials will be considered (section 1.2).

COOLING CIRCUITS TUBES CLEANING METHODS

All types of cooling waters can have different tendencies to corrode condenser materials and to introduce organic fouling and mineral scaling. This is why a strong control of the water is so important. It will prevent the formation of mineral scale, organic growth and corrosion.

In the case of seawater, care must be taken to control biological fouling, scale (particularly in heat exchangers), and the tendency to corrode many materials.

There are several kinds of condenser tubes cleaning procedures: physical screening, physical cleaning and chemical dosing [27], and almost all have been adopted in a large field of industries. High pressure cleaning, with a water flow pressure higher than 600 bar, is necessary to remove consistent macrofouling and calcareous settlements. In this case, oxide layers are completely removed from the metal surface. The in service continuous mechanical cleaning systems (like Taprogge system) are effective for the prevention of microfouling and it is one of the recommendable methods as Best Available Technologies [28] for cooling water circuits. In this case, sponge rubber balls, with the same density as water and a diameter slightly larger than the bore of the condenser tubes, circulate inside the pipes. This method can be effective enough for freshwater when macrofouling risk is low. But in the case of seawater, for which aggressiveness is highest and macrofouling settlement is an important issue, it has to be associated with a chemical treatment. In this case, as well as in all the cases for which a chemical solution is necessary to control macrofouling in the cooling tubes, the best solution often consists of a mechanical in-service cleaning associated with a chemical low-dosage treatment [29].

The most practical and efficient method applied to prevent and control biofilms and microbial activity in cooling water is the use of biocides. Biocides are single compounds (or a mixture of compounds) capable of killing microorganisms or inhibiting microbial growth.

CHLORINATION

Chlorine is the most common oxidizing biocide and is introduced either through the electrolysis of seawater or the injection of sodium hypochlorite solution. Chlorination treatments can be carried out either intermittently, keeping the residual chlorine level below 0.3 to 0.5 ppm [30, 31], or by using the so called shock method, i.e. 2-3 ppm chlorine at intervals of 1 hour for a limited period. Since high chlorine levels increase the susceptibility of copper alloys to erosion-corrosion, continuous low level chlorination is to be preferred [31].

Table of contents :

CHAPTER 1 – SCIENTIFIC BACKGROUND

1.1 Cooling water systems in power supply facilities

1.1.1 Types of condensers

1.1.2 Types of cooling waters

1.1.3 Constituent materials of cooling water systems

1.1.4 Cooling water systems operating problems

1.1.5 Cooling circuits tubes cleaning methods

1.1.6 Chlorination

1.2 Corrosion of copper and its alloys in aqueous environments

1.2.1 Galvanic corrosion

1.2.2 Pitting corrosion

1.2.3 Dealloying

1.2.4 Ammonia attack

1.2.5 Sulfide attack

1.2.6 Erosion-corrosion

1.2.7 Microbiologically influenced corrosion (MIC)

1.3 Effect of different parameters on the corrosion behavior of 70Cu-30Ni alloy and Al brass

1.3.1 Effect of iron and nickel

1.3.2 Effect of temperature

1.3.4 Effect of pH

1.3.4 Effect of oxygen content

1.3.5 Effect of polluted seawater

1.3.6 Effect of water velocity

1.3.7 Effect of seawater treatments

1.3.8 Effect of suspended particles and mud

1.3.9 Effect of biomolecules

1.4 Aim of this thesis and research strategy

1.5 Thesis outline

CHAPTER 2 – MATERIALS AND METHODS

2.1 Studied metallic materials and electrolytes

2.1.1 Metallic materials

2.1.1.1 Field experiments – electrodes and surface preparation

2.1.1.2 Laboratory experiments – electrodes and surface preparation

2.1.2 Electrolytes

2.1.2.1 Field experiments

2.2 Experimental methods

2.2.1 Field experiments

2.2.1.1 On-line measurements

2.2.1.2 Off-line measurements

2.2.2 Laboratory experiments

2.2.2.1 Electrochemical measurements

CHAPTER 3 – COPPER ALLOYS IN REAL INDUSTRIAL CONDITIONS: CORROSION AND MICROBIOLOGY

3.1 Power plants characteristics

3.1.1 Tests on the Tyrrhenian coast

3.1.2 Tests on the Adriatic coast

3.2 Electrochemical tools

3.2.1 Corrosion rate

3.2.2 Biofilm growth

3.2.3 Chlorination treatments

3.2.4 Other physico-chemical parameters

3.3 Results of the monitoring campaign

3.3.1 70Cu-30Ni alloy – Online measurements

3.3.2 Al brass – Online measurements

3.3.3 70Cu-30Ni alloy and Al brass – Off-line measurements

3.3.3.1 Visual observations

3.3.3.2 Weight loss measurements

3.3.3.3 Microbiological analyses

3.4 Conclusions

CHAPTER 4 – EFFECT OF SOLUTION AND BIOMOLECULE CONCENTRATION

4.1 Results

4.1.1 Electrochemical measurements

4.1.1.1 Corrosion potential (Ecorr) vs time

4.1.1.2 Cathodic and anodic polarization curves

4.1.1.3 Electrochemical Impedance Spectroscopy

4.1.2 Surface analysis

4.1.2.1 Equations necessary for XPS data processing

4.1.2.2 Results

4.2 Discussion

4.2.1 Surface layers models (combined XPS and ToF-SIMS)

4.2.2 Composition of the organic layers (XPS)

4.2.3 Corrosion mechanism

4.2.4 Impedance model for 70Cu-30Ni and EIS data fitting

4.3 Conclusions

CHAPTER 5 – EFFECT OF HYDRODYNAMICS

5.1 Static conditions vs under flow and stirring – Results

5.1.1 Electrochemical measurements

5.1.2 Surface analysis

5.1.2.1 Surface layers models (combined XPS and ToF-SIMS) M.L.CARVALHO

5.2 Electrochemical measurements using a RRE

5.2.1 Theory for a Rotating Ring Electrode

5.2.2 Results

5.2.2.1 70Cu-30Ni

5.2.2.1.1 Corrosion potential (Ecorr) vs time

5.2.2.1.2 Cathodic polarization curves

5.2.2.1.3 Levich and Koutecky-Levich curves

5.2.2.1.4 Anodic polarization curves

5.2.2.1.5 Electrochemical Impedance Spectroscopy

5.2.2.1.6 EIS data fitting

5.2.2.2 Al brass

5.2.2.2.1 Corrosion potential (Ecorr) vs time

5.2.2.2.2 Cathodic and anodic polarization curves

5.2.2.2.3 Electrochemical Impedance Spectroscopy

5.2.2.2.4 Impedance model for Al brass and EIS data fitting

5.3 Conclusions

CHAPTER 6 – EFFECT OF PH

6.1 70Cu-30Ni

6.1.1 Electrochemical measurements

6.1.1.1 Corrosion potential (Ecorr) vs time

6.1.1.2 Cathodic polarization curves

6.1.1.3 Anodic polarization curves

6.1.1.4 Electrochemical Impedance Spectroscopy

6.1.1.5 EIS data fitting

6.1.2 Surface analysis

6.1.2.1 Results

6.1.2.2 Surface layers models (combined XPS and ToF-SIMS)

6.1.2.3 Composition of the organic layers (XPS)

6.2 Al brass

6.2.1 Electrochemical measurements

6.2.1.1 Corrosion potential (Ecorr) vs time

6.2.1.2 Cathodic polarization curves

6.2.1.3 Anodic polarization curves

6.2.1.4 Electrochemical Impedance Spectroscopy

6.2.1.5 EIS data fitting

6.2.2 Surface analysis

6.2.2.1 Introduction

6.2.2.2 Results

6.2.2.3 Surface layers models (combined XPS and ToF-SIMS)

6.3 Conclusions

GENERAL CONCLUSIONS