Get Complete Project Material File(s) Now! »

Chapter III: Use of Electronic Nose Systems to Monitor the Effects of Cluster Thinning on Vitis vinifera L. cv. Merlot Grape and Wine Volatiles

Abstract

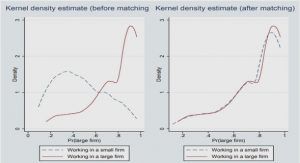

Cluster thinning is a common vineyard management practice used to increase fruit maturity rate and wine quality. In this study, grape and wine volatiles were analyzed on full cropped vines, 1 cluster/shoot and alternating 1&2 clusters/shoot treatments using a conducting polymer and surface acoustic wave-based electronic nose systems. Results from electronic noses were compared with physico-chemistry, GC/MS and wine aroma sensory evaluations. Using canonical discriminant analysis, physico-chemistry of grapes differentiated among all treatments only at harvest compared to differences found by both electronic nose systems on all sampling dates. Wine GC/MS analysis showed 100% discrimination using 32 volatile compounds identified from wines of all treatments out of which 25 compounds differentiated between treatments. Sensory analyses discriminated between the 1 cluster/shoot and 1&2 clusters/shoot treatments. Principal component analysis of grapes results indicated the conducting polymer-based system performed better in discriminating treatments (average of 81.9% using prin1) followed by physico-chemistry (64.7%) and surface acoustic wave-based system (61.1%). For wine both electronic noses were able to discriminate 100% of the replicates using canonical discriminant analysis, whereas with principal component analysis, CP-based system was able to explain 98% of the variation using prin1 compared to 56.9% by surface acoustic wave-based system. Both electronic nose systems performed better than other traditional methods used in this study.

Introduction

Cluster thinning (CT) is widely accepted as a beneficial vineyard management practice (Reynolds et al. 2007) though it involves increased labor and lower yield. It is essentially done to adjust the crop load in order to attain the highest sustainable yield, desired fruit maturation with varietal character and better wine quality (Keller et al. 2005, Reynolds et al. 2007). The level of cropping should be carefully decided, because over-cropping delays fruit maturation (Petrie and Clingeleffer 2006, Winkler 1954) and lowers the wine quality, color, pH and acidity (Weaver et al. 1957). Previous studies on CT show inconsistency in its effectiveness.

Dami and his group (2006) have shown that CT has an effect on the grape composition while Keller and his coworkers (Keller et al. 2005) have found in their study that the difference is negligible. Investigators have found that the cluster thinning increases the soluble solids and pH thus enhancing the juice composition (Dami et al. 2006). Increase in soluble solids is suggested to be because of the enhanced fruit maturity rather than the increased rate of sugar accumulation, which occurs as part of the change in berry growth phase (Petrie and Clingeleffer 2006). The treatment is also known to increase the number of berries per cluster and the cluster weight (Reynolds et al. 2007) compensating the yield loss to some extent.

The crop-level adjustment to low yields is known to increase the color of red wine (Bravdo et al. 1984). This finding is supported by the another study that shows an increase in anthocyanins concentration in cluster thinned vines (Petrie and Clingeleffer 2006). Wine made from these vines have a higher amount of acetyl ester and lower secondary alcohol giving it better aroma characteristics (Sinton et al. 1978). CT treatment enhances the monoterpene (the chemical class of compounds which are known to impart a distinctive wine aroma) levels in the fruit and this alteration also provides the desirable aroma and flavor attributes to the wine (Reynolds et al. 2007). There still exist other studies that show that there is little or no difference in the wine sensory properties due to CT despite the difference in grape composition observed (Bravdo et al. 1985, Ough and Nagaoka 1984, Reynolds et al. 2007). The current methods to analyze are time consuming, labor intensive and yet not adequate hence recent technologies need to be investigated.

The electronic nose (ENose) is an emerging technology used in areas like quality testing, process monitoring and storage in the food industry. Electronic nose systems are chemosensory-based and are classified based on their sensor type: metal oxide semiconductor (MOS), quartz microbalance (QMB), metal oxide semi-conductor field effect transistors (MOSFET), conducting polymer (CP) and surface acoustic wave (SAW) based systems. Mallikarjunan (2005) has reported that a major drawback of ENose systems are sensor drift and lack of consistency. According to him, developing optimum methodology and parameter settings specific for each product could partially help overcome these problems (Mallikarjunan 2005)

The CP system consists of 32 conducting polymer-based sensors formed electrochemically onto a carbon or silicon substrate. Polymers include polyaniline, polyprole, polythiophene, polyindole and polyacetylene of different oxidation and reduction states providing selectivity to different compounds (Mallikarjunan 2005, Pinheiro et al. 2002). Upon exposure to a chemical vapor, sensors expand causing a change in resistance, measured and stored as smellprint. The ‘smellprint’ is represented as bar graph, each bar demonstrating the resistance change of each sensor. This smellprint is stored in the database when a standard set of samples are introduced and unknown samples are identified by comparing the reading with the memory database (Cyrano SciencesTM Inc. 2000). The CP system provides better sensitivity and selectivity compared to other ENose systems and operates at moderate temperatures hence preventing the volatile breakdown due to increased heating of sensors (Mallikarjunan 2005).

SAW electronic nose system contains a single sensor, which simulates a virtual array as if consisting of hundred orthogonal sensors (Mallikarjunan 2005). This system adsorbs a chemical vapor and causes a change in sensor resonant frequency (Electronic Sensor TechnologyTM 2001). This system analyzes samples both quantitatively and qualitatively using both spectroscopic or chromatographic approaches (Lammertyn et al. 2004).

This study evaluated the impact of cluster thinning on grapes and wines using CP and SAW-based systems. The results from the electronic nose systems were compared with data from physico-chemistry, GC/MS and sensory analyses.

Materials and Methods

Field Design

This study was performed on Merlot grapes grown on a Ballerina training system in Charlottesville, Virginia, during 2008. Heat summation and average rainfall recorded in this growing season were 1154.4°C and 3 mm. Vines were planted in 1998 on a 20274.76 m2 dyke silt loam soil type plot with 3.05X2.13m spacing. The grapes were of clone FPS 3 and grated on 3309C rootstock. Treatment consisted of full crop, 1 cluster/shoot and 1&2 clusters/shoot thinned at veraison. Three sampling dates were chosen (once per week) on weeks 12, 13 and 16 post-bloom. Five grape vines were selected using a randomized block design from each of the treatments.

Degrees brix using refractometer (AO Scientific instruments© 10430, New Hampshire, USA), %RH using digital hygrometer (Traceable™ 4187, Texas, USA) and temperatures using infrared thermometer (Extech Instruments© 42529, Massachusetts, USA) were measured within the vine canopy between 08:00 – 11:00 hrs. Five clusters were collected from the neighboring vines or from vines not used for ENose measurements every week for laboratory analysis. At the end growing season, approximately 84 kg of grapes were harvested and were frozen for processing. The components of yield determined include shoots/meter, clusters/vine, cluster weight, berry weight, fruit weight/vine and fruit weight/treatment.

Laboratory Analysis (Berry/Juice/Wine Chemistry)

Twenty-five berries per vine were randomly selected from frozen clusters. Berries were weighed, thawed and crushed in 30.97 cm3 (15.24X20.32X0.10cm) volume plastic sampling bags (Minigrip®, Texas, USA), which approximately holds 200 grape berries. Juice was filtered through 0.45µm syringe filters (Whatman®, New Jersey, USA). The skins and the remaining juice were frozen for total glycosyl-glucose (TGG) and phenol-free glycosyl glucose (PFGG) analysis. Berry weight, Brix, pH and titratable acidity (TA) were determined as described by Zoecklein et al. (1999). Color intensity (A420 +A520), hue (A420/A520) and total phenols (A280) were determined using a Genesys™ 5 spectrophotometer (Spectronic, Leeds, UK). The TGG and PFGG analysis were performed according to methods described by Williams et al. (1995), as modified by Zoecklein et al. (2000). For wines, analyses of malic acid, fermentable nitrogen, alcohol content (v/v), residual sugar and volatile acidity were also conducted. L-malic acid was determined enzymatically (R-Biopharm AG, Darmstadt, Germany). Fermentable nitrogen was also determined enzymatically (Megazyme©, Bray, Ireland), alcohol content by FTIR (Foss WineScan™ FT 120, Minnesota, USA) and residual sugar concentration estimated by Clinitest (Bayer, Indiana, USA).

Wine samples for GC-MS analysis were prepared using 4 mL sample with NaCl salt (1.0 in 10 mL clear glass vials sealed with a septa (MicroLiter® Analytical Supplies, Inc., Georgia, USA). Vials had a pre-incubation time of 30 seconds at 30°C with agitation at 250 rpm. A CAR/DVB/PDMS Grey SPME Fiber (Supelco Sigma-Adrich, St. Louis, Missouri, USA) was used to penetrate vials to a 32 mm depth. A GC-MS (Agilent Technologies, 6890N Network GC System, 5975B inert MSD) with injector temperature of 250°C, DB-Wax column (30x25x25), and helium carrier gas with a flow rate of 1 mL/min were used. Oven temperature was 40°C with a ramp rate of 6°C per minute to 230°C. Thirty-two standard compounds from each wine sample were manually integrated and quantified.

Processing and Fermentation

Harvested grapes (26.7kg) from each treatment, frozen at -20°C were thawed for at least 24 hours prior to processing. Clusters were crushed and destemmed using a Wottle (Anton, Poysdorf, Austria) destemmer crusher to about 50% berry breakage, estimated visually. Berries were distributed into six open-top 60LNalgene fermenting bins of equal height and volume. Each bin was treated with 250mg/L Velcorin® (Scott Laboratories, California, USA) dimethyl-dicarbonate (DMDC) to sterilize juice from internal yeast or bacteria. Bins were held for 24 hours at 7ºC cooler followed by additional 25 mg/L of potassium metabisulfite (KMBS) addition. Grapes were cold soaked for 5 days at 7ºC during which must and grapes were punched daily.

Must juice analysis was performed on the 2nd day of cold soak and °Brix, pH, titratable acidity (TA), and fermentable nitrogen adjustments made; pH and TA adjustments using tartaric acid, °Brix using sucrose, fermentable nitrogen using FermAid®K (Lallemand, Blagnac Cedex, France) and diammonium phosphate (DAP).

Go-Ferm® (Lallemand, Blagnac Cedex, France) yeast nutrients were prepared according to manufacturer directions and added during the yeast rehydration. Saccharomyces cerevisiae ICV-D254 (Lallemand, Blagnac Cedex, France) yeast of 20g/L was inoculated following the cold soak treatment. After inoculation, caps were punched 3 times daily. Fermentation was monitored by hydrometer and proceeded at approximately 23±2ºC until dryness (<1% residual sugar). Following fermentation, wines were pressed using a basket press. Free run and press run fractions were separated into sanitized, carbon-dioxide filled carboys. Wine was kept at 7ºC for 24 hours, racked and filled in 3.80Land 1.90L glass bottles.

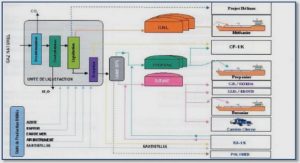

Electronic Nose Analysis

Two electronic nose systems, a conducting polymer-based, Cyranose 320™ (Smiths Detection©, Pasadena, CA, USA; both in field and laboratory) and a surface acoustic wave-based, ZNose 7300 ™ (Electronic Sensor Technology, Newbury Park, CA, USA) were used to determine the volatile differences among grapes and wine.

The CP ENose settings optimization for grapes was that of Athamneh et al. (2008) (Table 1A). For field analysis, one cluster was chosen at random from each of five selected vines. Clusters were bagged with a HDPE bag and received 45 minutes equilibrium time and same clusters were used for the ENose measurements on all sampling dates. In-field analysis of grape clusters using Cyranose is illustrated in Figure 1. Additional 5 clusters from neighboring vines were collected and frozen until laboratory analysis.

Wine evaluation optimization method for CP ENose is given in Table 1B (Gardner 2009). Wine was analyzed twice, once immediately post-fermentation and again 6 months post-fermentation. Five replicates of 20mL wine samples were placed in 40mL GC clear glass vials sealed with Teflon/Silicone 3 mm septa top (MicroLiter® Analytical supplies, Inc., Suwanee, Georgia, USA). The samples were analyzed subsequently by Cyranose after placing it in a water bath at 30°C for 20 minutes.

Abstract

Acknowledgements

Introduction and Justification

Chapter I: Review of Literature

Grape Maturity and Berry Development

Physiochemical maturity indices

Acids

Phenols

Aroma and Aroma-precursors of Grape and Wine.

Canopy Side

Ethanol Treatment

Electronic Nose

References

Chapter II: Electronic Nose Evaluation: Effects of Canopy Side on Cabernet franc (Vitis vinifera L.cv.) Grape and Wine Volatiles

Abstract

Introduction

Materials and Methods

Lab Analysis (Berry/Juice/Wine Chemistry)

Electronic Nose Analysis

Data Analysis

Results and discussion

Conclusions

References

Chapter III: Use of Electronic Nose Systems to Monitor the Effects of Cluster Thinning on Vitis vinifera L. cv. Merlot Grape and Wine Volatiles

Abstract

Introduction

Materials and Methods

Electronic Nose Analysis

Data Analysis

Conclusions

Chapter IV: Effects of Ethanol Spray on Cabernet franc and Merlot Grape and Wine Volatiles using Electronic Nose Systems

Abstract

Introduction

Materials and Methods

Results and Discussion

Conclusions

References

Summary and Conclusions

Appendix .

GET THE COMPLETE PROJECT

Discriminating the Effects of Vineyard Management Practices on Grape and Wine Volatiles from Cabernet Franc and Merlot Grape Varieties Using Electronic Nose Systems