Get Complete Project Material File(s) Now! »

High energy method

The droplets are generated by high-shear mixing or by sonication. Those systems are obtained with a large array of surfactants, and for a large water/oil/surfactant composition range. The droplet size can be tuned by varying the amount of energy input (rotation speed32, frequency34) and can be scaled to an industrial level. On the other side this energy can generate heat which is unfavorable in the presence of volatile oils or thermally fragile components35,36. Other techniques such as microfluidic flow focusing and membrane emulsification also exist, even though they are better adapted for industrial production, they require special equipment and are prone to coalescence37.

Low energy methods

Another way to generate nano-emulsions with a low energy input is to take advantage of the intrinsic physicochemical properties of the components of a system38. There are two classes of low energy approaches: the self-emulsification and phase inversion . The self-emulsification method also known as the “Ouzo effect” is the transformation of a microemulsion (thermodynamically stable system) into a nano-emulsion (kinetically stable system) by reducing the surfactant’s concentration via a simple dilution. It consists of an initial solution of oil, surfactant and a co-surfactant (such as ethanol) that is also soluble in the aqueous medium39,40. Then the simple addition of water will reduce the surfactant’s concentration (thus increasing the surface tension above 10-4 N.m-1 which is the upper limit for thermodynamic stability33) and generating an O/W emulsion in one step (Figure 1-8).

The phase inversion methods depend on the phase transitions of a system to generate nano-emulsions. Those phase transitions are associated with the ability of the surfactant to change its curvature during the emulsification process.

The curvature of the surfactant is negative when it forms a W/O emulsion, zero when it forms a planar film and positive when it forms an O/W emulsion (Figure 1-1). In the case of phase inversions mainly nonionic surfactants are used, their curvature can be changed by the modification of the hydration grade of the polar head in the surfactants molecules. The hydration grade can be controlled by modifying the temperature or the composition.

Liquid crystal/emulsion templating

This mechanism requires the presence of an initial macromolecular structure which will serve as an organic template. Those templates can be liquid crystals58, or emulsions59 or solid particles60. The silica precursor is added to the template, which condenses and polymerizes directly around the template. Finally, after the elimination of the template, the silica material assumes the shape and the organization of the organic template.

Hierarchically porous materials

Porous materials have found wide applications in many fields of chemistry such as catalysis, adsorption, electronics and environmental technology because of their high surface area coupled with many other physical and chemical properties61–64. Recent developments in research fields such as photonics, bioengineering and nanotechnology increased the need for a well-defined structural, interfacial, compositional and morphological properties which can only be offered in a material having a porosity at multiple scales. In catalysis, it has been reported that a hierarchal combination of pores reduces transport limitations and blockage, resulting in higher activities and better control over selectivity65.

Meso-macroporous materials

The increased demand for the encapsulation and release of large molecules with a big molecular weight such as proteins drove the researchers to develop porous silica materials with a large pore size (30 nm)66,67. These applications require porous materials with hierarchical pore structure at different scales in order to achieve highly organized functions and improve the diffusion of large molecules. The development of hierarchical porous materials at multiple scales was the subject of interest over the last few years. The presence of mesopores in the walls of the macropores is more interesting and useful for the catalysis and drug delivery systems. From an application viewpoint, drugs or catalysts can be loaded in the mesopores and in the micropores while the macropores enhance the mass transfer and reduce the transport limitations. This is particularly beneficial in the case of large molecules or in viscous systems where diffusion rates are low. For the sake of large performance improvement, such materials should possess adjustable and well-defined macropores and tunable mesopores in the macropore walls. On all length scales, the bigger pores should be connected via smaller pores. Thus it remains a challenge to synthesize hierarchically bimodal mesoporous-macroporous materials with controlled individual pore sizes and pore structures, although several methods have been reported that combine the individual process techniques of mesopore and macropore synthesis, for example, by dual templating of surfactant systems and colloids68.

In the synthesis of hierarchical meso-macroporous inorganic materials, self-assembled molecular aggregates or supramolecular assemblies are generally employed as the structure-directing systems of meso-structures. Meanwhile, a lot of techniques can be employed for the design of the macroporous network.

Polymer spheres templating

A general procedure of synthesis to generate the macroporous network requires the use of polymer spheres as templates. Colloidal polymer spheres, with a narrow size distribution, are left to aggregate in an organized manner. These colloidal spheres are submerged with the inorganic precursor and a micellar solution, then a condensation process is put in place. The surfactants and the spheres are either removed by calcination or solvent extraction. This leads to the formation of a three-dimensional ordered meso-macroporous material (3DOM)69–71.

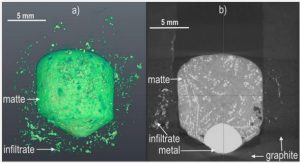

Tiddy et al.60 synthesized a series of hierarchically ordered porous silica composites with ordering on three different scales of pore size by using polystyrene spheres for the macropores and a mixture of triblock copolymers (pluronic F127 and P123) as templates in the presence of co-surfactants (n-alcohols) in an acidic medium. The silica materials consists of three-dimensional ordered macropores (200 – 800 nm) with interconnecting, uniform sized (70-130 nm) windows and the walls of these macropores consist of mesostructured pores (3 – 8 nm), as well as a significant microporosity presenting a macro-meso-microporous structure with a three-dimensional interconnectivity. The formation of windows is due to the close-packed arrangement of the spheres (touching points) (Figure 2-4). The meso- and microporosity are generated by the micelle formation of the block copolymers in the presence of the co-surfactant butanol or pentanol. The surface area and mesopore volume of the materials were low (46 m2/g and 0.053 cm3/g) when the latex spheres are removed by direct calcination at 550°C, while a high total surface area of 531 m2/g was obtained after extraction of the latex spheres using toluene which is then followed by a calcination at 450°C.

Bimodal mesoporous materials

Many papers can be found in the literature focusing on the synthesis of meso-macro, micro-macro or micro-mesoporous materials60,75,83,86–90. However only a few deal with bimodal systems having two types of mesopores 67,91–95. In addition, the final material has either a disordered bimodal mesopore arrangements or ordered mono-modal mesopore with small size template molecular systems embedded in larger entities.

One of the strategies to prepare bimodal mesoporous material consist in using mixtures of templates93–99. For example Chen et al. 98 employed mixtures of micellar solutions of nonionic surfactants including Pluronic, Brij and Tetronic types as templates for synthesizing porous silica materials having mixed pore sizes. Depending on the surfactant mixture, ordered uniform pore size arrangements, partially ordered complex bimodal structures or totally disordered non-mesoporous structures were obtained. Among the surfactant mixtures, the ones of fluorinated and hydrogenated surfactants are useful in specific practical applications, so these mixtures in aqueous systems have been widely investigated using different techniques such as light scattering, NMR and small-angle neutron scattering (SANS)100–103. In these systems, either mixed micelles containing both surfactants in a well-defined proportion, or two kinds of micelles enriched in one of the two components can be formed. In fact, fluorinated surfactants have chemical and physical properties that are different from the hydrogenated ones. Due to the difference in polarities between the fluorocarbon and hydrocarbon chains nonideal net repulsive interactions can occur.

Table of contents :

Chapter I

1 Surfactant systems

1.1.1 Molecular structure

1.1.2 Hydrophilic-lipophilic balance (HLB) system

1.1.3 Organized molecular assemblies

Nano-emulsions

2 Porous Silica Materials

Mesoporous Materials

2.2.1 Cooperative templating mechanism – CTM

2.2.2 Liquid crystal/emulsion templating

2.3.1 Meso-macroporous materials

2.3.2 Bimodal mesoporous materials

3 Application fields

3.1.1 Effects of porous silica materials properties on drug loading and release

3.1.2 Hybrid materials as carriers of active ingredients

3.1.3 Active ingredient: Ketoprofen

3.2.1 Lipase

3.2.2 Catalytic mechanism of the lipase

3.2.3 Enzyme immobilization on porous silica materials

3.2.4 Effect of the properties of porous material

4 Aim of this thesis

5 References

Chapter II

1 Materials

Oils

Silica source

Enzymes

2 Methods

2.1.1 Polarized light microscopy

2.2.1 Phase Inversion Composition – PIC

2.2.2 Phase Inversion Temperature – PIT

2.2.3 Conductivity measurements

2.2.4 Dynamic light scattering

2.2.5 Nanoparticle Tracking Analysis – NTA

Drug release

Transesterification

2.5.1 Enzyme physisorption on silica substrates

2.5.2 Adsorption isotherm

2.5.3 Transesterification of Colza oil

2.5.4 Purification of the transesterification reactions products

2.5.5 Gas chromatography

2.5.6 Yield calculation of the transesterification reaction

3 Characterization methods

3.1.1 Lamellar phase

3.1.2 Hexagonal phase

3.1.3 Mesoporous material

3.2.1 Type II isotherm

3.2.2 Type IV isotherm

Electronic microscopy

3.4.1 Scanning Electronic Microscopy – SEM

3.4.2 Transmission Electronic Microscopy – TEM

4 References

Chapter III Detailed investigation of nano-emulsions obtained from the Remcopal 4/decane/water system

Nano-emulsions as imprints for the design of hierarchical porous silica through a dual templating mechanism

Hybrid hierarchical porous silica templated in nano-emulsions for drug release

1 Biocompatible nano-emulsions

Characterization

Release Experiment of the Ketoprofen from the Biocompatible Nano-emulsions

Silica materials templating

2 References

Chapter IV

1 Introduction

2 Thermal stability of the hierarchically porous the silica material

Thermal stability of the dual-mesoporous silica materials

3 Hydrothermal stability of the hierarchically porous silica material

Hydrothermal stability of dual-mesoporous silica material

Comparison and discussion

4 Mucor miehei Lipase immobilization

4.1.1 Adsorption isotherm

4.1.2 Characterization of the meso-macroporous biocatalyst

4.2.1 Adsorption isotherm

4.2.2 Characterization of the dual-mesoporous biocatalyst

5 Transesterification reaction of colza oil

6 Discussion

7 Conclusion

8 References

9 Acylases immobilization

Adsorption isotherm

Conclusion

10 References