Get Complete Project Material File(s) Now! »

Polymer Electronic Composites that Heal by Solvent Vapour

This chapter was partially adapted with permission from:

Baek, P., et al. (2016). « Polymer electronic composites that heal by solvent vapour. » RSC Advances 6(100): 98466-98474, with permission of The Royal Society of Chemistry.

Abstract

Recent advances in organic electronic devices have reached a new milestone in performance and function, and are used in applications ranging from displays to sensory devices. However, they still present limitations in mechanical flexibility and electrical durability following the damages caused during their lifetime. In this Chapter a simple route to prepare conducting polymer composites that can address some of these issues through solvent vapour-induced healing of cracks formed within conducting polymer composites is presented. Conducting polymer composites were prepared by solution blending of poly(3-hexylthiophene) (P3HT) and poly(dimethylsiloxane) (PDMS)-containing urea segmented copolymer. The bicomponent composites with various weight fractions of neutral P3HT were used to demonstrate their electroactivity whereas the electrical conductivity, mechanical and solvent vapour-induced self-healing studies were carried out with composites with various weight fractions of FeCl3-doped P3HT. Mechanically bisected free-standing film with 30 wt% of doped P3HT was observed to be readily healed through exposure to solvent vapour at room temperature, with mechanical healing efficiency of 55 ± 24 % and restoration of electrical conductivity up to 82 ± 1%.

Introduction

Stretchable and flexible electronics are rapidly growing field that extends out to state of art displays, wearable devices, soft robotics and medical applications.[17, 189-191] For such electronics, there is a great demand for elastomeric and conductive materials that show sufficient conductivity at large strains and display healing properties which improve the device’s lifetime. Since traditional conductors based on metals are not intrinsically stretchable, various fabrication methods have been employed to make stretchable conductors, such as producing gold into wavy structures.[192] Other approaches are based on composite materials due to straightforward and low cost fabrication processes involved. Examples of composites include dispersing conductive fillers such as metallic nanoparticles,[193] carbon nanotubes[194] or graphene[195] within an elastomeric matrix such as polyurethane (PU) or poly(dimethylsiloxane) (PDMS). However, processability remains as a challenge for such composites, which has often led to inhomogeneous dispersion of the filler components.[17, 189] Conducting polymers (CPs)[20, 24, 196, 197] have been considered as a great candidate as the active component in composites for flexible and stretchable organic thin film electronic devices.[17] They have unique electrical, optical and redox properties that are chemically tuneable. Additionally, chemical derivatisation of the CP backbone by side chains increases its solubility, hence affording processability.[16, 70] Since CPs alone are limited in flexibility or stretchability owing to their rigid π-conjugated backbone,[189] CP composites with traditional elastomers such as PU or PDMS have been fabricated.[125, 127, 129, 198] CP composites can be prepared by direct solution blending of a CP and elastomer solutions, generally requiring soluble CPs.[125, 129, 198] Li et al.[129] demonstrated bicomponent solution blending using PEDOT:PSS with various soft polymers such as poly(ethylene glycol), poly(ethylene oxide), and poly(vinyl chloride) to give highly conductive and elastomeric electrodes. Despite the high conductivity of PEDOT:PSS, it is only soluble in water, thus limiting its solution blending to only water soluble polymeric elastomers. On the other hand, poly(3-alkylthiophene)s such as poly(3-hexylthiophene) (P3HT) have been used to demonstrate solution-blending with traditional elastomers such as PDMS.[198, 199] Recently, Lee et al.[198] and Song et al.[200] presented a facile route to homogeneously blend P3HT/PDMS films as the semi-conducting layer in organic field-effect transistors. Based on these reports, P3HT is a suitable material for components in stretchable electronics. The electrical conductivity of P3HT can be easily achieved via various doping methods while retaining the polymer’s solubility in its doped state.[201-203]

PDMS has been widely used as the elastomeric substrate for stretchable electronics.[17] PDMS are generally chemically crosslinked in order to be used as elastomers. Non-chemical crosslinking methods towards PDMS elastomers with improved mechanical strengths have been also demonstrated.[204-209] Specifically, segmented copolymers, with PDMS as the soft component and urea or urethane as the hard component, have shown similar behaviour to thermoplastic elastomers due to the dynamic hydrogen bonding between the urea or urethane functional groups.[207-209] Recently, Cui et al.[188] demonstrated self-healing polymer system using PDMS-containing urea (PDMS-urea) segmented copolymer. The mechanically bisected supramolecular polymer showed healing efficiency of 50%, where healing is thought to have occurred through disassembly and assembly of the polymer network at the surfaces of the damaged site when brought together. The self-healing required elevated temperatures (> 50 oC) or significantly long time (> 2 weeks) at room temperature. On the other hand, others have shown more efficient crack repair of thermoplastics by manual intervention,[210] which involved immersing the elastomer into a solvent to promote healing through the entanglement of the polymer chains by lowering the effective glass transition temperature below room temperature.[211]

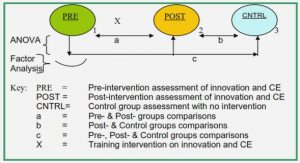

Inspired by the notion, the idea of making CP-based flexible conductive polymer composites was concerned with incorporating self-healing properties of PDMS-containing urea segmented copolymer, whereby PDMS-urea copolymer is solution blended with neutral or FeCl3-doped P3HT. The bicomponent composite material with various weight fractions of neutral P3HT were used to demonstrate their electroactivity, whereas the electrical conductivity, mechanical and self-healing studies were carried out with composites with various weight fractions of doped P3HT. Thin films of P3HT composites showed excellent electroactivity while thin films of doped P3HT composites showed a percolation weight fraction of 30%. A free-standing film with 30 wt% of doped P3HT was further examined for self-healing under a solvent vapour, and the recovery of the electrical and mechanical properties was evaluated. The mechanically bisected composite film was manually pressed together then exposed to tetrahydrofuran solvent vapour at room temperature. 30 min of solvent vapour exposure led to mechanical healing efficiency of 55 ± 24% and recovery of 82 ± 1% of its conductivity.

Experimental Section

Chemicals

3-Hexylthiophene (99 %), bis(3-aminopropyl) terminated poly(dimethylsiloxane) (average Mn 2500), tolylene-2,4-diisocyanate (95 %), and tetrabutylammonium hexafluorophosphate (TBAHFP, 99 %) were purchased from Sigma-Aldrich and used as received. Iron (III) chloride (FeCl3) was purchased from ECP chemicals and used as received.

Chemical Oxidative Polymerisation of 3-hexylthiophene

A typical chemical oxidative polymerisation of 3-hexylthiophene was performed according to Amou et al.[157] To a nitrogen-purged solution of anhydrous FeCl3 (0.65 g, 0.0040 mol) and chloroform (2.0 mL), 3-hexylthiophene (0.17 g, 0.0010 mol) was added dropwise and the mixture was stirred at room temperature for 24 h under nitrogen atmosphere. The resulting polymer was precipitated in cold methanol followed by filtration. The precipitate was then washed with methanol (24 h) and extracted with chloroform (24 h) in a Soxhlet extractor. The volatile solvent was removed to give neutral P3HT. Yield: 0.11 g (65 %).

Doping of P3HT for Blending

The neutral P3HT dissolved in chloroform was chemically doped by adding dropwise a 1 M solution of FeCl3 (2 mol eq.) in acetonitrile and stirring for 6 h under nitrogen atmosphere. The chemically doped polymer was precipitated in cold methanol and filtered to give black solids. Doped P3HT was stored in dark under N2 atmosphere before further use.

Synthesis of PDMS Segmented Urea Copolymer (PDMS-urea)

PDMS-urea was synthesised according to Yilgor et al.[207] To a deoxygenated, anhydrous solution of tolylene-2,4-diisocyanate (0.17 g, 1.0 mmol) in tetrahydrofuran (THF) (7.0 mL), PDMS-NH2 (2.6 mL, 1.0 mmol) was added and stirred for 24 hr. The resulting viscous solution was stored under nitrogen atmosphere until further use.

Preparation of P3HT/PDMS-urea Composites

Various weight ratios of P3HT and PDMS-urea were prepared as follows: solutions of various weight fractions of neutral/doped P3HT and PDMS-urea in THF were prepared to make a total polymer concentration of 30 mg/mL and were stirred under a nitrogen atmosphere for 12 h to give a clear solution. The composite solution was kept in a nitrogen atmosphere in dark before further use. For thin film studies, neutral or doped P3HT composite solutions were spin coated at 2000 rpm for 60 s onto bis(trimethylsilyl)amine (HMDS) silanized glass slides with sputtered parallel gold contacts with a distance of 10 mm or indium tin oxide (ITO) coated glass slides (area of 1 cm2), respectively. Gold contacts were sputtered coated to a clean glass substrate using Model Q150RS (Quorum Technologies Ltd.) through a shadow mask (10 mm). Following the casting, the samples were then dried at 40 oC for 5 min under vacuum and stored under a nitrogen atmosphere before measurements. Free-standing composite film with 30 wt% doped P3HT was prepared by casting the 30 mg/mL composite solution in a Teflon well then placing it in an oven at 60 oC for 20 min, followed by leaving it under a nitrogen atmosphere for 12 hr. Thickness of the film was controlled by the amount of solution casted.

Solvent Vapour-induced Healing of Free-standing Films

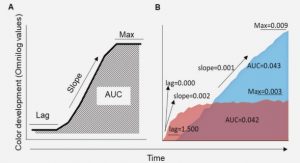

For mechanical studies, parallel specimens with dimensions (length, width, and thickness) of 54 x 7.0 x 0.80 mm for PDMS-urea and 54 x 5.0 x 0.80 mm for 30 wt% P3HT composite film samples were mechanically bisected with a sharp scalpel and were brought into contact and left in a glass chamber under a THF vapour atmosphere (19.8 kPa) at room temperature (22.550 oC) for various time intervals up to 30 min. The glass chamber had an approximate volume of 5 L and 20 mL of THF was placed inside the chamber to create a THF vapour environment. After the exposure, samples were dried in vacuum for 10 min prior to measurements. Mechanical healing efficiency was defined toughness, which was calculated as the area under the stress-strain curve.[187]

For scanning electron microscopic (SEM) images and electrical studies of the 30 wt% P3HT composite film, parallel specimens with dimensions of 20 x 6.5 x 0.20 mm were used and the same cutting and healing procedure was conducted as mentioned above. Electrical healing efficiency was defined by Ro/Rt, where Ro and Rt are the resistance before cutting the composite and after various solvent vapour exposure time, t, of the bisected composite.

Characterisation

NMR spectroscopy

1H NMR was performed on a Bruker 400 MHz with as-prepared P3HT dissolved in CDCl3. The HT content of P3HT was estimated by the ratio of integrals of peaks appeared at 2.8 (HH) and 2.6 (HT) p.p.m. in 1H NMR.[157]

FTIR spectroscopy

FTIR measurements were carried out using a Bruker Vertex 70 FTIR spectrometer.

Determination of molecular weights using GPC

Molecular weights of P3HT and PDMS-urea were determined TDAmax GPC system (Malvern Instruments) attached with 2 x T6000M (300 mm x 8 mm each) Viscotech columns (Malvern Instruments). The columns and the detectors were maintained at 35 oC. THF filtered through 0.22 µm PTFE membrane filter (Grace) was used as eluent with the flow rate of 1 mL min-1. 100 µL of polymer solutions at concentration of 5 mg mL-1 were injected into the column. All samples were filtered through 0.22 µm PTFE syringe filters (Grace) before injection. Triple point detection was used for calibration and the calibration curve was plotted using polystyrene standards purchased from Sigma Aldrich. Data acquisition and processing were performed using the OmniSEC software (Malvern Instruments).

CV measurements

CVs of the spin coated composites on ITO coated slides were measured using a CH Instruments (650 model) electrochemical workstation with the ITO as the working electrode, a platinum wire as the counter electrode and Ag/AgCl wire as the reference electrode in 0.1 M TBAHFP in acetonitrile (N2 purged) for various scan rates (25 – 300 mV s-1). The thickness of spin coated composite thin films were measured using a Digimatic Indicator (ID-H Series 543). All thin film samples had an average thickness of 1 ± 0.5 µm. Thickness of free-standing films were measured with an electronic digital calliper.

Investigation of doping process using spectroelectrochemical measurements

Using the same setup described in the CV section, UV-Vis-NIR spectra of the spin coated composites on ITO coated slides in 0.1 M tetrabutylammonium hexafluorophosphate (TBAHFP) in acetonitrile (nitrogen purged) were initially recorded in its neutral state in a 3 mL quartz cuvette using Shimadzu UV-3600plus spectrophotometer. Potentials were incrementally stepped every 0.1 V from +0.2 to +1.2 V using a CH Instruments (650 model) electrochemical workstation with ITO as the working electrode, a platinum wire as the counter electrode and Ag/AgCl wire as the reference electrode. Each potential was held constant for 30 s prior to taking an UV-Vis-NIR spectra.

Healing of electrical properties

For electrical healing test of the free-standing 30 wt% P3HT composite films, resistance was measured using a Digitech QM1549 digital multimeter.

SEM measurements

SEM images were taken with an FEI (Philips) XL30 S-FEG instrument or a JCM-6000 PLUS NeoScope benchtop instrument. All samples were sputter coated with Pt.

Electrical measurements

Current-voltage curves of the thin film composites were measured in ambient conditions using a Keithley 228 source meter.

Water contact angle measurements

Static contact angles of deionized water droplets on various surfaces were measured using a KSV instruments CAM100 contact angle meter. The size of the droplets were monitored and controlled using the CAM100 software.

Stress-strain measurements

For tensile tests, parallel specimens with dimensions (length, width, and thickness) of 54 x 7.0 x 1.0 mm for PDMS-urea and 54 x 5.0 x 1.0 mm for 30 wt% P3HT composite samples were used. The tensile measurements were performed on an Instron 5567 with 50 N load cell. The crosshead speed was set to 500 mm min-1 and the distance between the grips were 35 mm. All specimens had a nominal gauge length of 25 mm.

Table of Contents

Abstract

Acknowledgements

Research Outputs

Awards

List of Abbreviations

List of Figures

List of Tables

List of Schemes

1 Introduction

1.1 Stretching the Limits of Conducting Polymers

1.2 Introduction to Conducting Polymers

1.3 Conducting Polymer Based Stretchable Electronics

2 Methodologies

2.1 Synthesis of Polythiophene Derivatives and Polymer-grafted Polythiophenes

2.2 Neutron Scattering Techniques for Probing the Structure of Polymers in Films and in Solution

2.3 Electrochemistry

2.4 Atomic Force Microscopy

2.5 Tensile Test

3 Polymer Electronic Composites that Heal by Solvent Vapour

3.1 Abstract

3.2 Introduction

3.3 Experimental Section

3.4 Results and Discussions

3.5 Conclusion

4 Molecularly Engineered Intrinsically Healable and Stretchable Conducting Polymers

4.1 Abstract

4.2 Introduction

4.3 Experimental Section

4.4 Results and Discussions

4.5 Conclusion

5 Chain Shape and Thin Film Behaviour of PTh-g-PAU

5.1 Abstract

5.2 Introduction

5.3 Experimental Section

5.4 Results and Discussions

5.5 Conclusion

6 Conclusions and Future Work

6.1 Conclusions

6.2 Future work

References

GET THE COMPLETE PROJECT

Stretchable and Self-healing Conducting Polymers for Organic Electronics